Beauty Begins with Attention to Detail

Finishing Quality Assessment

Recyc's bottle defects inspection meticulously assesses the finishing quality of sustainable containers and provides a comprehensive report detailing all potential defects, complete with photos and standardized defect names. Curious about the specific elements Recyc inspects? Explore our primary checklist of finish defects.

-

Split Finish

Split Finish

-

Crumbles

Crumbles

-

Deformation

Deformation

-

Molded Seam

Molded Seam

-

Out of Vertical Finish

Out of Vertical Finish

-

Hammered Appearance

Hammered Appearance

-

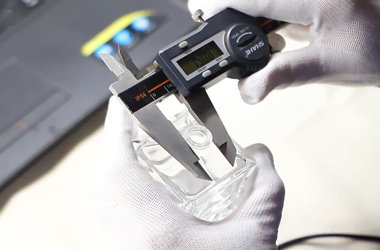

Thin Walls

Thin Walls

-

Blisters

Blisters

-

Cord

Cord

Physical and Volume Inspections

A superior container is one that smoothly traverses the client's filling line without complications and possesses the durability to securely transport their product to the end consumer. Consequently, prior to a container leaving the bottle manufacturing facility for sale, it is imperative that it undergoes a rigorous evaluation against functional standards meticulously crafted to align with customer requirements.

Our check points

-

Appearance inspection

-

Cadmium(Cd)

-

Lead(Pb)

-

Arsenic(As)

-

Antimony(Sb)

Physical performance regulations

| Item | Standard |

|---|---|

| Appearance inspection | No burrs, cracks, tear and chipped finish |

| Cadmium(Cd) | ≤ 0.25 mg/L |

| Lead(Pb) | ≤ 0.5 mg/L |

| Arsenic(As) | ≤ 0.15 mg/L |

| Antimony(Sb) | ≤ 0.5 mg/L |

Quality Assurance is a Collective Endeavor

Crafting high-quality bottles necessitates a collective commitment, with line operators, cleaning and changeover crews, as well as manufacturing and packaging management working hand in hand. Our inspection technologies deliver precise data readings, complemented by the keen judgment of our inspectors, enabling us to faithfully adhere to your specifications.

Consult Your Recyc Bottles & Packaging Experts

We help you avoid the pitfalls to deliver the quality and value your glass bottle and jar need, on-time and on-budget.

Contact Recyc