How Eco-Friendly Glass Bottles Are Manufactured at Recyc

Located in Jiangsu, China, Recyc’s advanced facility produces over 500,000 sustainable glass bottles daily. Serving the beverage, food, and cosmetic industries, we utilize cutting-edge technology and deep industry knowledge to deliver premium packaging solutions. Our glass bottle production process includes raw material crushing, blending, precision batching, melting, forming, and annealing—each stage optimized to meet the exact specifications of your product. Recyc is committed to quality, customization, and sustainability throughout every phase of bottle manufacturing.

Full Capacity in Our Sustainable Bottle Manufacturing Plant

-

5000+

- Instock styles -Having a large in-house mold inventory offers unmatched flexibility, ensuring faster, cost-effective solutions beyond the limitations of a single factory.

-

700,000+

- Pcs of bottles daily -Accelerate time-to-market with our efficient bulk production, enabling businesses to streamline processes and respond swiftly to market demands.

-

8

- Production lines -Reduce costs on low-volume orders with Recyc’s flexible production lines, capable of handling diverse bottle designs simultaneously.

How To Make Sustainable Bottles Step By Step

1 Essential Raw Materials for Sustainable Glass Bottle Production

Sustainable glass bottles are made from sand, soda ash, limestone, and recycled glass (cullet). These ingredients form soda-lime glass, the industry standard. For specialty bottles, colorants or compounds like borosilicate are added to enhance durability, heat resistance, or visual appeal, ensuring eco-friendly and versatile packaging.

-

Sand

Sand

-

Soda ash

Soda ash

-

Limestone

Limestone

-

Cullet

Cullet

2 Precision Batching in Sustainable Glass Bottle Manufacturing

The batching process involves accurately measuring and mixing raw materials before they’re sent to the melting furnace. This critical step ensures consistent glass quality and performance. Precise batch sizes are tailored to production volume and bottle design, supporting efficient, high-quality sustainable bottle manufacturing.

3 Eco-Friendly Melting in Sustainable Bottle Production

In our fully automated furnaces, raw materials are melted at 1600°C, evaporating moisture and incinerating organics to form high-quality molten glass. Engineers control temperatures via advanced software, ensuring consistent viscosity for forming—supporting precision, energy efficiency, and sustainability in the glass bottle manufacturing process.

4 Sustainable Blow Forming Techniques for Glass Bottles

Molten glass is portioned and dropped into molds using precision timing. Forming methods like Blow and Blow or Press and Blow shape the final bottles efficiently, ensuring consistent quality and sustainability in custom glass bottle production.

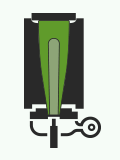

Blow and Blow Glass Bottle Forming Method

The Blow and Blow process uses compressed air to shape molten glass into a parison, then reheats and expands it into its final form. Ideal for producing narrow-neck bottles like wine, beer, and soda containers.

Gob dropped into black mold

Gob dropped into black mold

Neck formed

Neck formed

Blank blown

Blank blown

Blank shape

Blank shape

Blank transferred to blow mold

Blank transferred to blow mold

Final shape blown

Final shape blown

Finished bottle

Finished bottle

Press and Blow Glass Bottle Forming Method

The Press and Blow method combines a plunger and compressed air to shape molten glass, creating wide-mouth containers like candle jars, vases, and milk bottles. Ideal for precise, consistent glass packaging production.

Gob dropped into black mold

Gob dropped into black mold

Plunger presses blank shape

Plunger presses blank shape

Blank pressed

Blank pressed

Blank shape

Blank shape

Blank transferred to blow mold

Blank transferred to blow mold

Final shape blown

Final shape blown

Finished jar

Finished jar

5 Annealing and Conditioning in Sustainable Bottle Production

After forming, glass bottles enter an annealing lehr for gradual reheating and controlled cooling. This process relieves internal stress, enhances durability, and ensures uniform glass structure. At Recyc, we carefully monitor annealing to ensure material consistency, minimize breakage risks, and deliver high-quality, sustainable glass bottles for various industries.

Trusted Sustainable Bottle Manufacturer in China with 9+ Years Experience

Recyc is a leading sustainable bottle manufacturer in China, offering over 9 years of industry expertise. We deliver high-quality eco-friendly packaging solutions tailored to your needs. From design to delivery, our strict quality control and customer-first approach ensure reliable, sustainable bottles that exceed expectations and support your brand’s green goals.

Consult Your Recyc Bottles & Packaging Experts

We help you avoid the pitfalls to deliver the quality and value your recyclable bottle and jar need, on-time and on-budget.

Contact Recyc