Precision-Driven Quality Control for Sustainable Bottles

Comprehensive Bottle Finish Inspection for Superior Quality

Recyc conducts thorough inspections to evaluate the finishing quality of every sustainable glass container. Our defect assessment includes detailed reports with images and standardized defect terminology. Want to know what we check? Discover our essential checklist of finish defects to ensure top-tier bottle quality and performance.

-

Split Finish

Split Finish

-

Crumbles

Crumbles

-

Deformation

Deformation

-

Molded Seam

Molded Seam

-

Out of Vertical Finish

Out of Vertical Finish

-

Hammered Appearance

Hammered Appearance

-

Thin Walls

Thin Walls

-

Blisters

Blisters

-

Cord

Cord

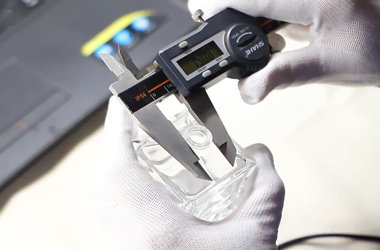

Physical and Volume Testing for Reliable Sustainable Bottles

Before leaving our facility, each Recyc bottle undergoes strict physical and volume inspections to ensure seamless compatibility with client filling lines and safe end-user delivery. Our testing protocols are tailored to meet precise customer requirements, guaranteeing optimal functionality, durability, and performance for every sustainable glass container.

Our check points

-

Appearance inspection

-

Cadmium(Cd)

-

Lead(Pb)

-

Arsenic(As)

-

Antimony(Sb)

Physical performance regulations

| Item | Standard |

|---|---|

| Appearance inspection | No burrs, cracks, tear and chipped finish |

| Cadmium(Cd) | ≤ 0.25 mg/L |

| Lead(Pb) | ≤ 0.5 mg/L |

| Arsenic(As) | ≤ 0.15 mg/L |

| Antimony(Sb) | ≤ 0.5 mg/L |

Collaborative Quality Assurance in Sustainable Bottle Manufacturing

Achieving top-tier bottle quality at Recyc is a team effort involving operators, technicians, and quality control staff. Our advanced inspection technologies and experienced inspectors ensure each bottle meets your exact specifications. This integrated approach guarantees precision, consistency, and sustainable excellence throughout the production process.

Consult Your Recyc Bottles & Packaging Experts

We help you avoid the pitfalls to deliver the quality and value your recyclable bottle and jar need, on-time and on-budget.

Contact Recyc